Diamond Lappato Abrasive Fickert Polishing Tool

Share By:

distributors wanted

we are looking for distributors globally.

Lappato Abrasive

The “Diamond Lappato Abrasive Polishing Tools” are specialized abrasive tools used in the surface treatment and polishing of ceramic tiles to achieve a distinctive finish known as the “Lappato finish” or “Lappato effect.” This type of abrasive tool is designed for precision and effectiveness in the tile manufacturing process. Here’s an explanation of each component in the name:

Diamond Lappato Abrasive: This refers to the abrasive material used in the tool. Diamond abrasives are known for their hardness and durability. They consist of tiny diamond particles embedded in a bonding material. Diamond abrasives are highly effective for grinding and polishing hard materials like ceramic tiles.

Ceramic Tile Surface Treatment Polishing: These tools are used for the treatment and polishing of ceramic tile surfaces. The treatment involves grinding and polishing the tile’s surface to achieve a specific texture and finish.

Lappato Finish: The Lappato finish is a distinct type of finish characterized by a semi-gloss surface with a satin-like texture. It combines both matte and glossy elements, creating a visually appealing and textured appearance on the tile’s surface. Achieving a Lappato finish typically involves using diamond abrasives and specialized tools to selectively remove material from specific areas of the tile, creating a controlled contrast between polished and matte sections.

In summary, the “Diamond Lappato Abrasive Ficket Polishing Tools for Ceramic Tile Surface Treatment Polishing” are specialized diamond abrasive tools used in the tile manufacturing process to achieve the unique and visually appealing Lappato finish on ceramic tiles. These tools play a crucial role in creating a controlled texture and finish on the tile’s surface, enhancing its aesthetic appeal.

Efficient

Replacing Magnetic Abrasives With Higher Production Efficiency.

Long Lasting

Special Recipe Of Fickert To Lower Operating Power.

Smoother

Better Heat Dissipation, More Delicate Substrate, And Smoother Surface Of The Finished Product.

More Homogeneous

More Uniform Mixing Of Resin With Diamond Brings More Stable Performance.

Fickert is the Diamond Tools for auto-polishing lines for lapping Tile/Stone Surface Treatment.

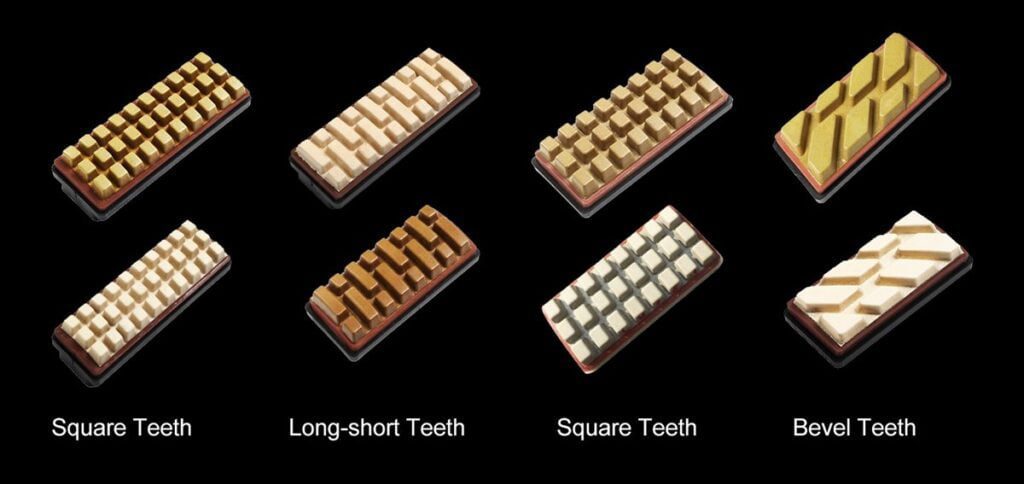

| Length/Size Type | L90, L140, L170 mm |

| Used For | Ceramic, Porcelain, Granite, Quotaze, Stone, Marble |

| Number of Teeth | 0/1/4/10/12-17/18-22 Inserts |

| Shape of Teeth | Square/Bevel/Helical |

| Used For | Tile or Stone Surface Finishing |

| Length | 90 140 or 170 mm |

| Tooth Shape | Square Bevel or Long&Short |

| Bond Method | Resin Bond |

| Grit Level | 80-10000 # |

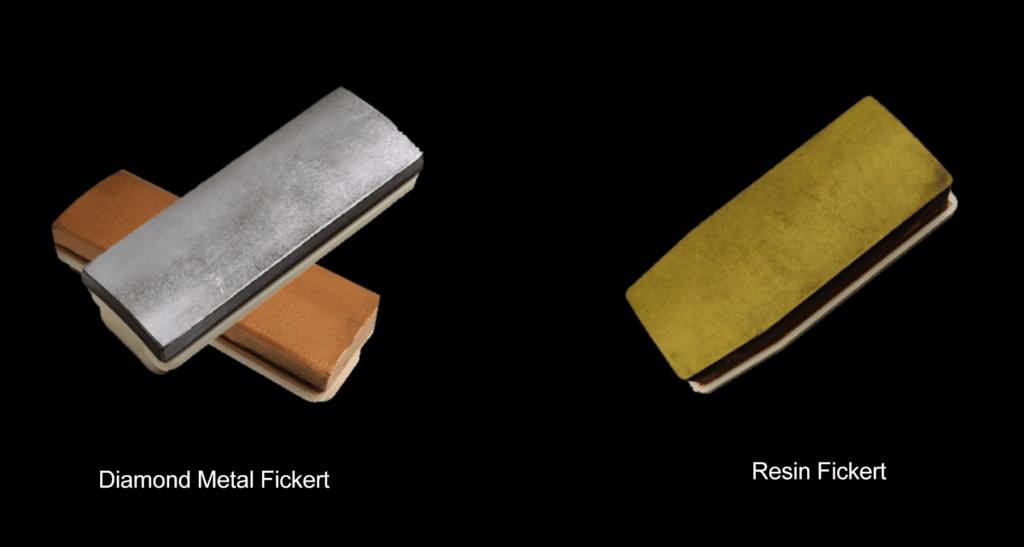

| Diamond Grinding | Resin Grinding | |

| Used For | Tile or Stone Surface Treadment Finishing | |

| Lengh | 90 140 or 170 mm | |

| Tooth Shape | No Tooth | |

| Bond Method | Metal Bond | Resin Bond |

| Diamond Powder | Diamond | No Diamond |

| Grit Level | 36-400 # | 240-10000 # |

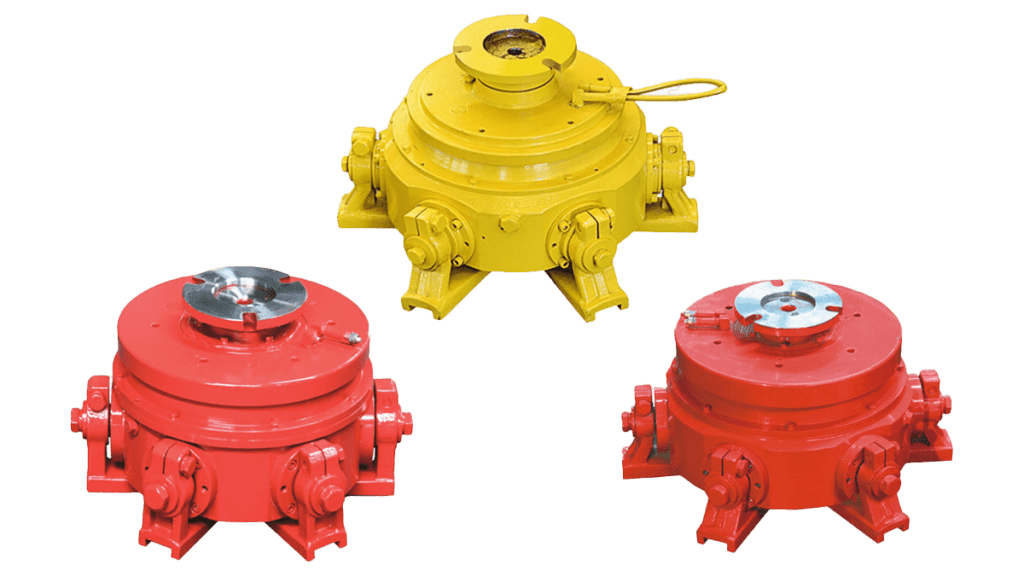

Magnesite Fickert is intended for granite calibration and rough grinding. For Automatic Polishing Lines, Automatic Bridge Polishing Machine, and Radial Arm Manual Polishing Machine;

| Used For | Granite,Basalt,Quartzite |

| Lengh | 140 160 170 mm |

| Tooth Shape | 1 |

| Bond Method | Magnesite Bond |

| Grit Level | 12 – 1800 |

Ficket Polishing Tools for Stone Processing

Ficket Polishing Tools, often referred to as Fickert Abrasive Tools, are specialized abrasives exclusively designed for the stone processing industry. These tools play a crucial role in the grinding and polishing of stone surfaces, delivering several key advantages:

Energy Efficiency: Ficket Polishing Tools are engineered to be exceptionally sharp, reducing the stress on grinding heads. This sharpness not only extends the lifespan of grinding equipment but also contributes to energy savings during stone processing.

Improved Productivity: Their superior sharpness enhances the transmission speed of conveyor belts, leading to increased production efficiency. Stone processing operations benefit from higher output and quicker turnaround times.

Enhanced Glossiness: Ficket tools have the capacity to significantly elevate the glossiness of stone surfaces. They can achieve a shine that exceeds standard levels, adding an exquisite finish to stone products.

Reliable Quality: Manufactured using advanced technology and precision equipment, Ficket Polishing Tools maintain consistently high quality. Rigorous quality control measures ensure that they meet industry standards, providing a cost-efficient solution for stone processing needs.

In summary, Ficket Polishing Tools are purpose-built abrasive tools exclusively used in the stone processing industry. Their sharpness, efficiency, ability to enhance glossiness and commitment to quality make them indispensable tools for achieving superior stone surface finishes.

Download PDF Catalog

Download Catalogs Now!

Our Company

About Us

Basair® is a tile production line machinery manufacturer from China. We have been manufacturing tile machinery since 2006. We provide tile production machine lines, parts, and consumables to more than 120 tile manufacturers around the world.

Our Factory

Our Exhibition

Our Certificates

Our Clients

How Many Steps To Buy Machine From Basair?

Pre-Sale Service

Inquiry & Consulting Support

View Our Factory

Vist Our Clients & Learn More

In-Sale Service

One-Stop Solution Supplier.

- Make us clear about your needs;

- We will follow the needs to design and quote;

- We will produce the machine after you confirmed them;

- Live the production process for you to ensure delivery;

After-Sales Service Support

On-site technical support.

- Providing support throughout the product life cycle.

- After-sales service includes warranty service, training, or repair for a product.

- achieve the timely procurement of parts

Loading & Delivery

Packing

Loading

Delivery

Frequently Asked Questions

My previous device was Ancora, Keda, MSB or BMR brand, will there be any adaptation issues between machine?

There will be no machine adaptation problems. All our devices are fully compatible with mainstream devices on the market, including some core accessories are interchangeable designs.

Do you provide operation training?

Yes. We provide global on-site technical support services (Include on-site technical Operation Training) . Wherever our equipment goes, our engineers will be there.

How much you save by importing from China?

The costs and fees can vary significantly on the importing country, . But generally , importing from China, you will save 30-80%.

How to become your local regional agent?

We are glad to add-values businesses to whole world partners. We provide agents with lower prices, stable quality, and quantity. As well as market material support and customer resource sharing.

How to import goods from china?

Imported goods can be as simple as one touch point end to complete door-to-door entry. We provide you with a full range of import service solutions.

how about your payment method?

We accept DP /DA /LC /TT /CAD /OA (Not all countries accept). Pls Contact Us First.

What is your tax & fee saving plan?

We have two manufacturing plants, and the consumables (Squaring Wheels & Lapping Fickert) required for the equipment will be exported together with the machine. Will save you a lot of import taxes&shipping fee.

How to install the machine if i buy them?

We provide on-site technical support services to our global customers. No matter where you are! We provide one-stop solutions of machines and services for the whole life from design, manufacturing, transportation, installation, commissioning, after-sales, consumables, accessories and other products.

How do you control the quality?

Our key position employees have more than 5 years of work experience. This will ensure that our products are installed by experienced technical engineers in strict accordance with the operation manual. The work of controlling quality starts at the source. Each purchased part is loaded into the machine only in one condition, and that is to pass inspection. Our electrical components are sourced from world-renowned companies. Japan's Omron, Germany's Siemens, France's Schneider, etc. We continuously improve the manufacturing process and optimize the production process in our production work. while improving quality control. The machine will undergo a 72-hour aging test before leaving the factory to make the equipment stable in all aspects.