Anyone who wants to grow up their own business. Whether it is a small workshop or a big factory.

If you want to buy machines for production. You need to face questions like this:

what’s the type of machine to buy?

How many machines should buy if I want to increase my production capacity plan?

How do I make the right choice for my factory of machines to improve product quality and capacity?

Here are a few machine buying tips that will help you in your business growth journey.

First, The quality of production stability is very important for factory production. This should be the highest priority.

Increasing assembly line efficiency can only be achieved by ensuring that the equipment is functioning normally. Once the machinery fails, the entire production line will be dragged down.

So, stable mechanical quality is the first.

The Chinese people’s pursuit of efficiency is very fanatical, which is a global consensus. Because of the huge output, in the factory in China, the production volume of a polishing production line per day (24 hours) is amazing. 84% of the production enterprises can reach 20,000-40,000 square meters per day.

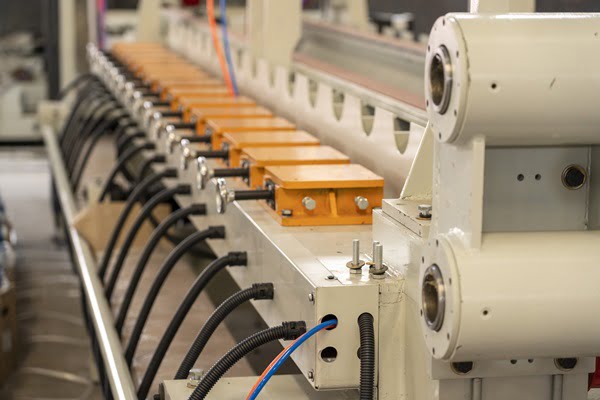

The conveyor belt speed of Basair’s machinery is 25-66 m/min. This high-speed machinery continues to be favored by more than 40% of China’s ceramic tile enterprises. In China, More than 40% of the tile manufacturers choose basair machinery. In the past 18 years, Basair has cooperated with more than 260 ceramic tile manufacturers around the world. Include tile manufacturers like Turkey, Indonesia, India, Pakistan, and other countries.

A stable and widely tested mechanical product must be the cornerstone of your business growth.

Second, reasonable product pricing.

In the past few years, the world has been affected by the epidemic and local turmoil. The global inflation level has been rising, and the economic situation has entered a cold winter. How to buy high-end machinery on a lower budget is everyone’s want.

It is difficult to ask a user to analyze the difference between Mercedes-Benz and Chevrolet from a technical level. How to judge whether a machine has a suitable price is a bit too much for a user.

Here are very simple judgment criteria for reference:

1. Does the business survive long enough?

Because the production of mechanical equipment has very high requirements on the process and process, the trial and error cost of the tile manufacturers (users) in the market is very high.

Therefore, manufacturers must exist long enough, and always focus on a narrow field of expertise and continuous improvement, in order to gain market recognition and survive.

The product pricing of such a manufacturing company is highly likely to be very reasonable.

2. Is the industrial chain developed?

The manufacture of machinery and equipment requires the cooperation of multiple industries and products and has the characteristics of the highly industrialized division of labor and cooperation.

It involves cooperation in electrical, machining, welding, assembly, rubber, and other fields. The integrity of China’s industrial chain is the world’s leading company.

Basair is located in Foshan and Guangdong, and it is also the hometown of ceramic tiles in the world.

Here, the upstream and downstream industries are concentrated and have the world’s leading scale advantage. More than 30% of the tiles in the world are manufactured here.

Excellent industrial clusters and complete supply chain support will greatly reduce manufacturing costs and improve product quality.

3. Is it convenient to transport?

Ceramic machinery is huge. The more links there are in transportation, the more likely it will lead to unpredictable accidents.

Foshan, where Basair is located, has convenient transportation and a dense water network. It only takes 30 minutes to reach the port.

Greatly reduces the accident risk of transportation.

Finally, don’t go too far in automation.

In the past 20 years, the automation of mechanical equipment has been a very good direction, reducing the dependence on manpower, and making it more convenient and efficient.

However, the more complex the system, the more fragile it is. This is one of the basic rules of this world. Basair has the deepest insight into the user: the user only wants a machine that can work stably and normally, not a professional repairman.

How can this be done?

We made some adjustments:

1. Increase the number of PLCs in the equipment, which will increase our cost, but also bring the benefit of non-stop maintenance. Our polishing machines can be repaired and maintained on any polishing head without stopping the machine.

2. Carefully use electronic equipment in machinery, especially components that are sensitive to the working environment. Because the working conditions of the machine are difficult to predict, the environment may be very harsh: dusty, humid, vibration, voltage instability, or even improper use. We use mechanical components instead of electronic components wherever possible because doing so makes our machinery easier to maintain and find suitable replacement parts.

3. . . .

The above are some of my sharing. If it is helpful to you, I hope you can share it with more people.