Tile production is a critical component of the building and construction industry. The demand for high-quality tiles has increased in recent years, leading to increased competition and the need for efficient and cost-effective tile production solutions. Squaring machine lines are an excellent solution for businesses looking to improve their tile production processes. In this article, we will explore the benefits of squaring machine lines, cost-effective solutions for improved tile production, and how to choose the right squaring machine line for your business.

The Benefits of Squaring Machine Lines

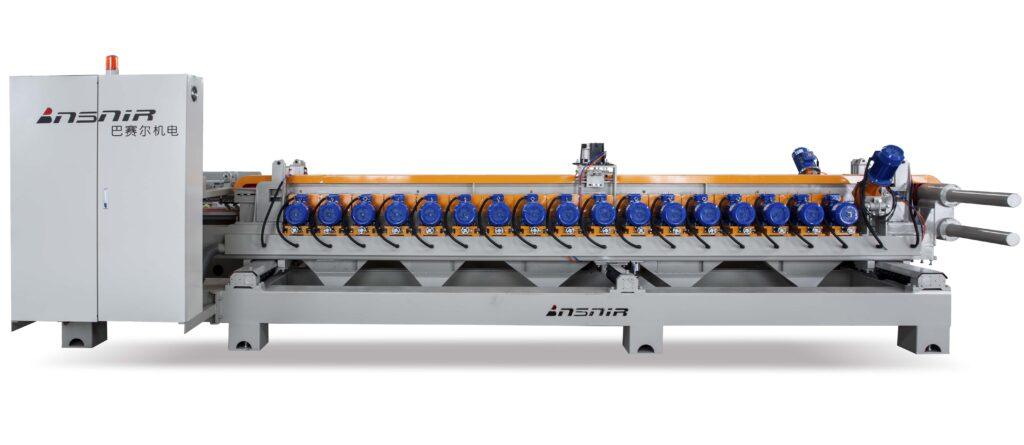

Squaring machine lines are essential in the tile production process, as they are responsible for producing square and precise edges on tiles. These machines have numerous benefits, including increased production speed, improved precision and accuracy, reduced labor costs, and enhanced product quality.

Increased production speed is a major benefit of squaring machine lines. These machines can produce tiles at a much faster pace compared to manual methods, allowing businesses to meet demand and improve production efficiency. Additionally, the improved precision and accuracy of squaring machine lines result in higher-quality tiles, which are more likely to meet customer expectations and reduce the need for rework.

Reduced labor costs are another critical benefit of squaring machine lines. Automating the tile squaring process eliminates the need for manual labor, reducing the costs associated with hiring and training workers. This results in lower overhead costs and increased profitability for businesses.

Finally, the enhanced product quality achieved through the use of squaring machine lines is a key benefit. High-quality tiles are in high demand, and businesses that produce them are more likely to succeed in a competitive marketplace. The precision and accuracy of squaring machine lines ensure that each tile meets the desired specifications, resulting in a consistent and high-quality final product.

Cost-Effective Solutions for Improved Tile Production

Investing in a high-quality squaring machine line is a cost-effective solution for improved tile production. These machines are designed to meet the specific needs of tile production processes, providing businesses with a flexible and customizable solution. Customized squaring machine lines can be designed to integrate with existing production processes, resulting in a seamless and efficient production experience.

Another cost-effective solution for improved tile production is the integration of energy-efficient technologies. Squaring machine lines that incorporate energy-efficient technologies, such as energy-saving motors and intelligent controls, result in lower energy consumption and reduced operating costs. This results in a more environmentally friendly production process, as well as lower prices for businesses.

Choosing the Right Squaring Machine Line for Your Business

When choosing a squaring machine line, it is important to consider the specific needs of your business. Different squaring machine lines offer different features and capabilities, and it is essential to choose the right equipment for your specific production requirements.

Working with experienced suppliers and manufacturers is critical to the success of your squaring machine line investment. These experts can provide valuable insights into the features and capabilities of different squaring machine lines, and assist in selecting the right equipment for your business.

Finally, research and testing are essential in the selection process. Before making a purchase, it is important to research and tests different squaring machine lines to ensure that they meet your business’s and production processes’ needs. This will help to ensure that you choose the right equipment and maximize your investment.

Conclusion

Squaring machine lines are a cost-effective solution for improved tile production. These machines provide numerous benefits, including increased production speed, improved precision and accuracy, reduced labor costs, and enhanced product quality. Investing in a high-quality squaring machine line, incorporating energy-efficient technologies, and working with experienced suppliers and manufacturers can help to ensure that you choose the right equipment for your business. Additionally, research and testing can help to ensure that your investment is maximized and that the squaring machine line meets the needs of your production process.

In conclusion, squaring machine lines are an excellent solution for businesses looking to improve their tile production processes. These machines provide a cost-effective and efficient solution for producing high-quality tiles while reducing labor costs and enhancing production speed. With the right squaring machine line, businesses can improve their production process, meet customer demand, and remain competitive in the building and construction industry.

Related Contents:

- What is the Squaring Machine Line & Line Polishing Machine Used for in Ceramic Production?

- Elevating Your Tile Production Process: The Power of Line Polishing Machines

- What Are the Types of Squaring Wheels?

- How to Adjust Your Squaring Machine to Meet Production Needs and Enhance Tile Quality

- The Best Squaring Machine Line in the World: Discovering BASAIR’s Innovative Solutions

- Why should you import tile machinery from China?

- 16 Heads Polishing Machine Line

- 12 – 20 Heads Polishing Machine Line

- 6 – 10 Heads Polishing Machine Line