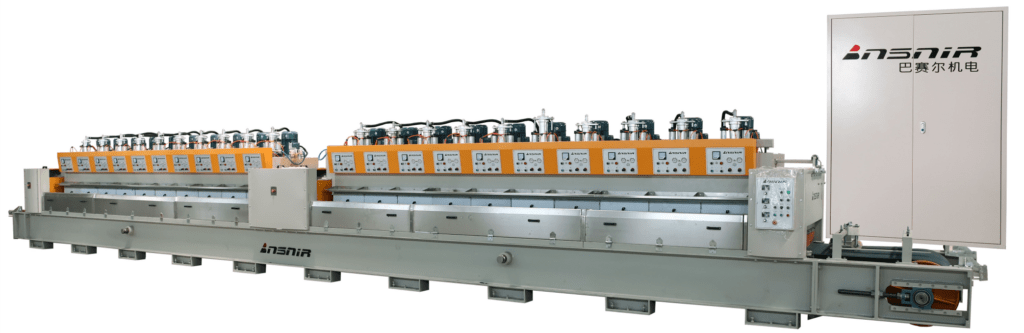

Line Polishing Machine For Ceramic Tile Production

Share By:

distributors wanted

we are looking for distributors globally.

Basair™ Line Polishing Machine is used for lapping, satin finishing, and polishing tiles. Our machines grind the surface of the tile to obtain the desired gloss on the surface of polished or glazed tiles.

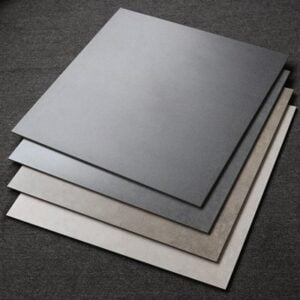

Machine Use For Polishing Tile Slab Stone Surface

Ceramic Tile

Glazed Tile / Polished Tile

Stone Slab

Granite Marble Quartz

Video Of Line Polishing Machine For Ceramic Tile Production

| Model No. | BSP600 | BSP800 | BSP1000 |

| Min. Workable Size (mm) | 300 | 300 | 300 |

| Max. Workable Size (mm) | 600 | 800 | 1000 |

| Max. Workable Thickness (mm) | 3 – 30 | ||

| Feeding rate (m/1′) | 10-40 | ||

| Polishing Spindles | 6 – 20 | ||

| Polishing Head Claws | 2 – 6 | ||

| Power Of Polishing Spindles (kw) | 11 – 15 | ||

| Power Of Main Transmission (kw) | 15 | ||

Download PDF Catalog

Download Catalogs Now!

Product Features

Foundation Structure - Structural Beams

The second quenching processes eliminate the internal stress of the material caused by welding and high-temperature cutting. Prevent any slight potential deformation of the material and keep the working surface level.

Conveyor Belt

We choose to use big brands products, the belts are more flexible and run more smoothly. Special underside weave design for thicker, tighter and more wear-resistant fiber coverage. Increase the strength of the belt, reduce the friction with the machine, the belt life will be longer, the tiles are moved more smoothly, and improved the quality of tiles.

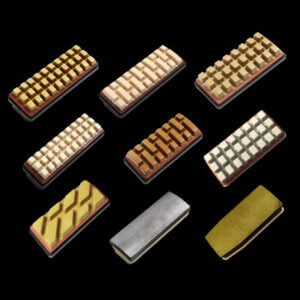

Polishing Head

Basair polishing machine thread head is one of the core components of the polishing machine. We use the same products as our KEDA machine line to ensure parts are easier to repair and replace. Corresponding KEDA machine line part numbers: KD268C, KD261E, KD269A.

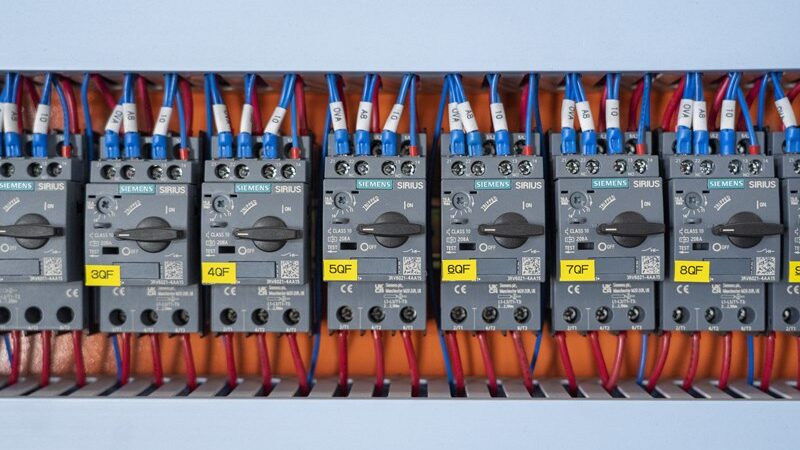

Electric switch

International brand, SIEMENS. Ensure stable production. Using mature products in the market, it is easier to repair and replace.

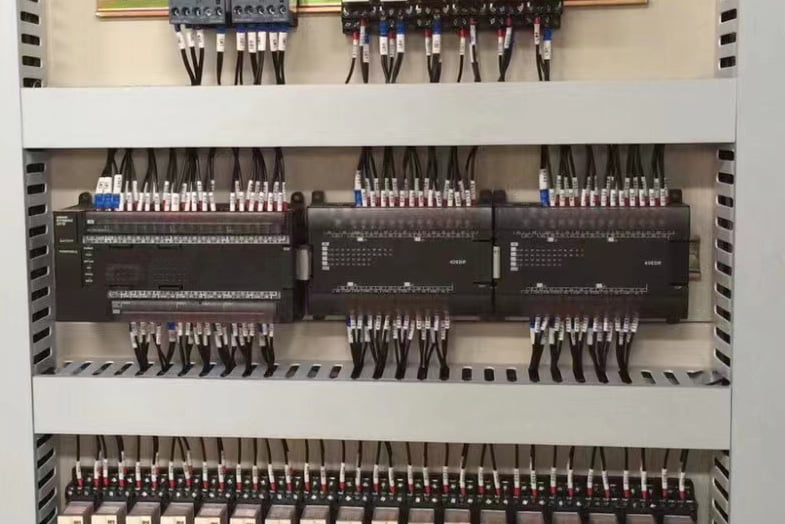

PLC

International brand, Omron. Ensure stable production.

Products Of Line Polishing Machine For Ceramic Tile Production

Our Company

About Us

Basair® is a tile production line machinery manufacturer from China. We have been manufacturing tile machinery since 2006. We provide tile production machine lines, parts, and consumables to more than 120 tile manufacturers around the world.

Our Factory

Our Exhibition

Our Certificates

Our Clients

How Many Steps To Buy Machine From Basair?

Pre-Sale Service

Inquiry & Consulting Support

View Our Factory

Vist Our Clients & Learn More

In-Sale Service

One-Stop Solution Supplier.

- Make us clear about your needs;

- We will follow the needs to design and quote;

- We will produce the machine after you confirmed them;

- Live the production process for you to ensure delivery;

After-Sales Service Support

On-site technical support.

- Providing support throughout the product life cycle.

- After-sales service includes warranty service, training, or repair for a product.

- achieve the timely procurement of parts

Loading & Delivery

Packing

Loading

Delivery

Frequently Asked Questions

My previous device was Ancora, Keda, MSB or BMR brand, will there be any adaptation issues between machine?

There will be no machine adaptation problems. All our devices are fully compatible with mainstream devices on the market, including some core accessories are interchangeable designs.

Do you provide operation training?

Yes. We provide global on-site technical support services (Include on-site technical Operation Training) . Wherever our equipment goes, our engineers will be there.

How much you save by importing from China?

The costs and fees can vary significantly on the importing country, . But generally , importing from China, you will save 30-80%.

How to become your local regional agent?

We are glad to add-values businesses to whole world partners. We provide agents with lower prices, stable quality, and quantity. As well as market material support and customer resource sharing.

How to import goods from china?

Imported goods can be as simple as one touch point end to complete door-to-door entry. We provide you with a full range of import service solutions.

how about your payment method?

We accept DP /DA /LC /TT /CAD /OA (Not all countries accept). Pls Contact Us First.

What is your tax & fee saving plan?

We have two manufacturing plants, and the consumables (Squaring Wheels & Lapping Fickert) required for the equipment will be exported together with the machine. Will save you a lot of import taxes&shipping fee.

How to install the machine if i buy them?

We provide on-site technical support services to our global customers. No matter where you are! We provide one-stop solutions of machines and services for the whole life from design, manufacturing, transportation, installation, commissioning, after-sales, consumables, accessories and other products.

How do you control the quality?

Our key position employees have more than 5 years of work experience. This will ensure that our products are installed by experienced technical engineers in strict accordance with the operation manual. The work of controlling quality starts at the source. Each purchased part is loaded into the machine only in one condition, and that is to pass inspection. Our electrical components are sourced from world-renowned companies. Japan's Omron, Germany's Siemens, France's Schneider, etc. We continuously improve the manufacturing process and optimize the production process in our production work. while improving quality control. The machine will undergo a 72-hour aging test before leaving the factory to make the equipment stable in all aspects.